The EC Elecylinder from IAI

Simple Operation without Programming

You can quickly setup just by entering data. You can also operate it with ON / OFF signals, like a solenoid valve.

No time-consuming programming is necessary.

Easily Register the Start and End Points at Any Position

Easily Adjust AVD Settings Individually

Enter the movement conditions.

Air cylinders adjust velocity by adjusting the air flow rate using flow valves. Fine adjustment of velocity, acceleration and deceleration is not available.

With the ELECYLINDER, AVD can be entered individually in percentages to apply adjustments.

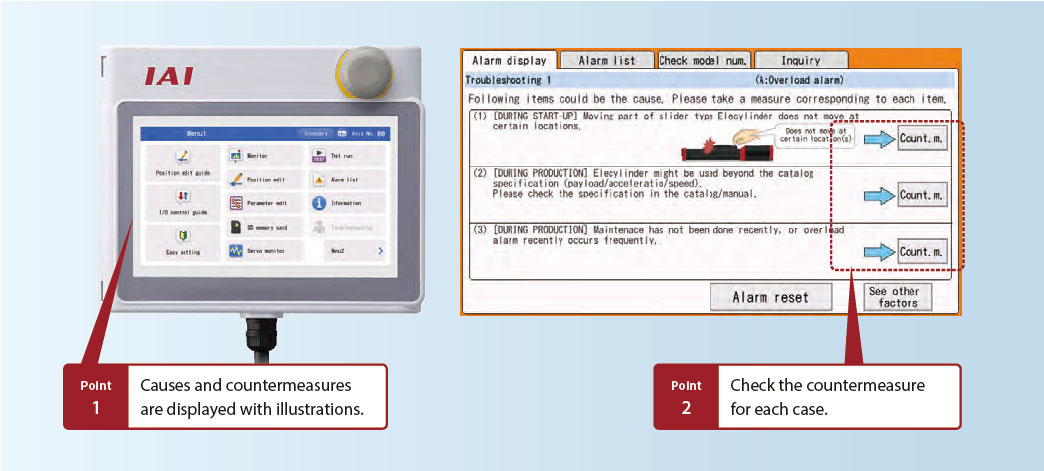

Easily Repairable in the Event of a Breakdown

Troubleshooting can be performed using the teaching pendant.

Device stoppage causes and countermeasures are displayed.

In nearly all cases, just replace the motor or controller circuit board yourself and the unit will recover.

Easily Reduce Cycle Time

Air cylinders cannot operate at high velocity due to the impact at stroke ends which occurs when excess velocity is applied.

The ELECYLINDER can start and stop smoothly at high velocity, reducing cycle time.

Long Service Life

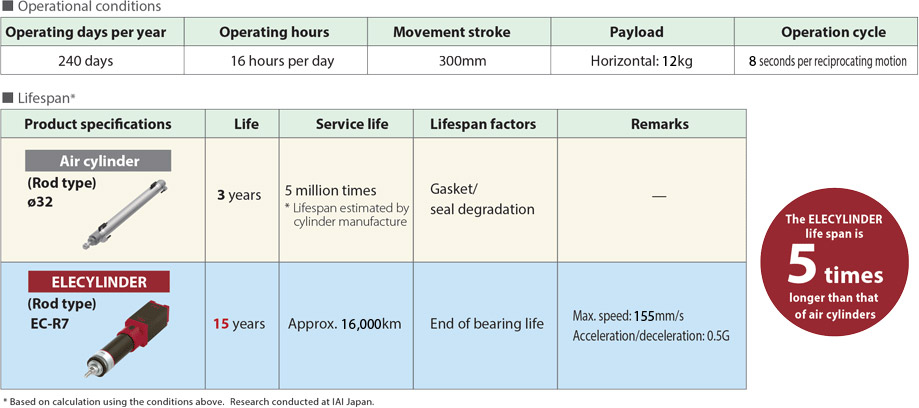

Instead of an impact mechanism, the ELECYLINDER incorporates a ball screw and ball circulating type built-in linear guide to achieve a long service life.

Based on calculation using the conditions below, the lifespan of the ELECYLINDER is five times longer than that of air cylinders.

Reduces Electricity Bills

The difference in the rate of power consumption for the ELECYLINDER and air cylinders depends on the operational frequency. The higher the operational frequency, the more effective the energy-saving becomes.

Based on tests conducted by IAI, the ELECYLINDER’s power consumption under the following conditions is 1/6 that of air cylinders.

Click here for more information and product catalog.

For more information on the ELECYLINDER contact any one of the team members @ Blettner Engineering or by calling 317-862-9580.