Factory Automation Conveyor Systems from mk North America

As industrial demand for reduced overhead costs and increased efficiency grows, so too does the demand for manufacturing process and factory automation. Factory automation helps manufacturers to increase production rates, material efficiency, worker safety, flexibility, and more, all while bringing down overall costs.For almost any industrial process, conveyors are one of the most crucial components of a comprehensive factory automation system. mk North America is a leader in industrial automation, providing modular pallet conveyor systems, belt conveyors, sanitary conveyors, and more including custom conveyor design to meet specific demands.

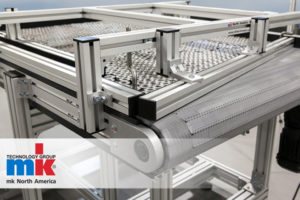

VersaMove Pallet Conveyor Systems for Factory Automation

Among mk’s most popular products, VersaMove conveyors are modular pallet conveyor systems that come in three configurations: the VersaMove Standard, VersaMove Plus, and VersaMove Ultra.Highly versatile and useful for a variety of industrial applications, VersaMove pallet transfer systems are ideal for factory automation. The SRF-P 1010 and ZRF-P1010, under the Standard configuration, are respectively well-suited for accumulation and indexing applications, each with pallet loads of up to 80 lbs. The VersaMove Ultra’s SRF-P 2012, meanwhile, is designed for the creation of heavy-duty systems capable of carrying as much as 700 lbs. per pallet.Combined with conveyor system modules like pallet lift and locates, lift and rotates, and right angle pallet transfers, these pallet transfer systems are capable of a variety of factory automation tasks as diverse as quality control, building automation, general material handling, and more.

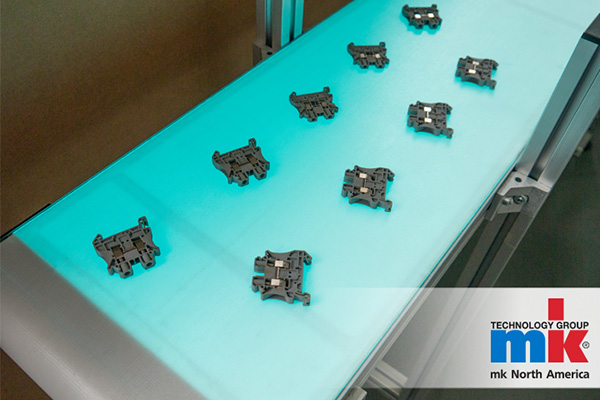

Other Factory Automation Conveyor Systems

Flat belt, cleated belt, modular plastic belt, and other conveyors made with mk aluminum t-slot extrusion create even more possibilities for modern factory automation. The MBF-P 2040.02 is a modular plastic belt conveyor designed for applications involving heavy material handling such as general manufacturing, as well as those requiring contact with high temperatures. Special conveying applications requiring positioning or loading of products are well-served by the ZRF-P 2040.02, an attachment timing belt conveyor designed for indexing applications.