nnrnnnrnnnThere’s more to many modern conveyors than just some rollers and a belt. Conveyor equipment is machinery as like any other, requiring regular maintenance to work its best. Whether you’re trying to keep an old conveyor system as long as possible before replacing it or being proactive in keeping a newer system shiny and new, the following are universal best practices to keep your belts moving and gears turning.nnrnnnrnnnNote: Any maintenance or inspection of a conveyor or other industrial equipment should be done by trained, qualified professionals with power off and all proper lockout/tagout procedures in place.nnrn

nnrnnnrnnnThere’s more to many modern conveyors than just some rollers and a belt. Conveyor equipment is machinery as like any other, requiring regular maintenance to work its best. Whether you’re trying to keep an old conveyor system as long as possible before replacing it or being proactive in keeping a newer system shiny and new, the following are universal best practices to keep your belts moving and gears turning.nnrnnnrnnnNote: Any maintenance or inspection of a conveyor or other industrial equipment should be done by trained, qualified professionals with power off and all proper lockout/tagout procedures in place.nnrn

rn

Ensure proper use of all conveyor systems.

rnnnThis should go without saying, but conveyor misuse is an extremely common cause of damage and premature wear. Make sure that conveyors aren’t being overloaded or run at too-high speeds; this can lead to overstress of the system’s gears, motors, and more. In general, units should be used as designed and described by the manufacturer.nnrn

rn

Make sure all maintenance and repairs are performed by trained personnel.

rnnnConveyors are specialized machines, and require someone who knows what they’re looking at to diagnose and maintain. Hire qualified maintenance employees rather than relying on untrained opinions from line workers or other employees.nnrnnnrn

Maintenance should be regularly performed.

rnnnThis means sticking to a schedule, and working down an established checklist. Checks should be performed regularly, as often as possible.nnrnnnHere’s a good sample checklist for a general conveyor system:nnrnnnnn

rnnnnn

- Visual check – look for obvious wear, damage, or unusual equipment behavior.

nnnnrnnnnn

- Ensure all safety guards and covers are in place.

nnnnrnnnnn

- Cleanliness check – make sure dust, dirt, debris, and other accumulations are cleared from the surface of the conveyor.

nnnnrnnnnn

- If any belt misalignment has been observed by workers or inspectors during operation, be sure to correct the tracking to its intended position. Depending on the system, belt alignment may have to be performed while the belt is in motion; be sure to observe all necessary safety precautions as laid out by the manufacturer and OSHA.

nnnnrnnnnn

- Check any pneumatic components are operating at proper pressure levels.

nnnnrnnnnn

- Check motor for proper function. Excessively hot motors should be replaced, as this is an indication of strain.

nnnnrn

nnnnrnnnrn

Keep good records.

rnnnAny time there’s an inspection or repair, anything observed or replaced should be meticulously detailed in company records. This will help identify patterns that can lead to better routine maintenance and better use of equipment for the best performance down the line.nnrn

rn

The manufacturer knows best.

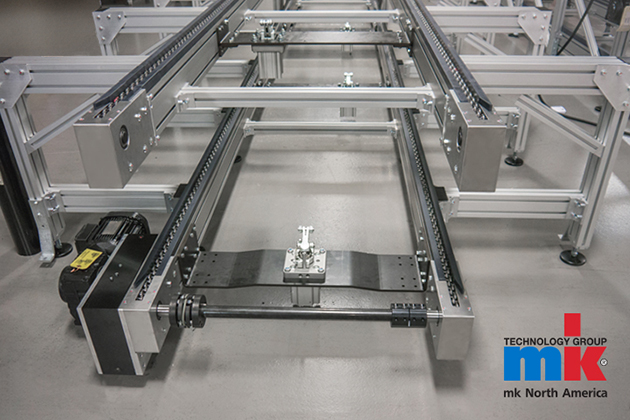

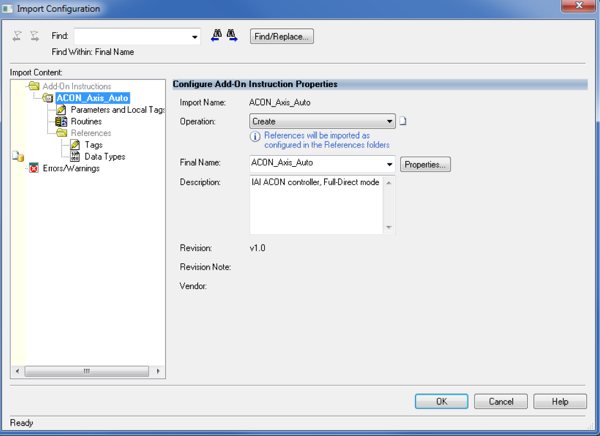

rnnnAt the end of the day, no one knows how to take care of a conveyor system better than the people who designed and manufactured it. Maintenance should be performed per the manufacturer’s recommendations and instructions, with due consideration for individual use.nnrnnnrnnnIf you’re in the market for new, custom conveyor systems, mk North America is a worldwide leader in belt, roller, pallet, and other conveyors for a variety of material handling applications.nnrnnnrnnnrnnnrnnnrnnnrnnnrnnnrnnnrnnnrnnnnn

nnrnnn nnrnnn

nnrnnn nnrnnn nnrnnnrnnn

nnrnnnrnnn