Over Under Conveyors from mk North America

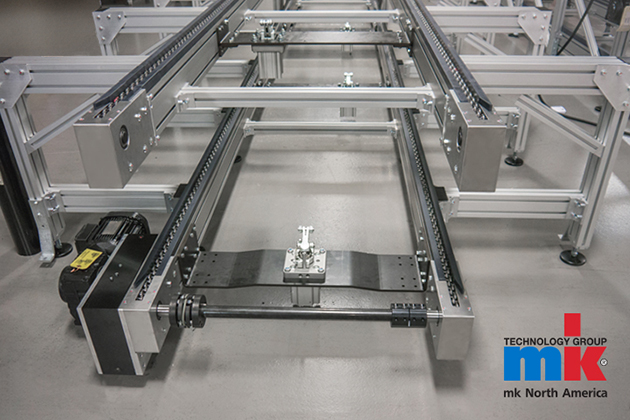

Created using our VersaMove pallet conveyor systems, over under conveyors from mk North America consist of two or more conveyor lines stacked on top of each other. Pallets move between each level with an elevator or vertical transfer unit on each end. This configuration allows human or robotic operators to work on upper conveyor lines while empty pallets recirculate on lower levels. However, the VersaMove system is completely modular and custom configurations can be easily created to meet your specific needs.

Features and Benefits of Over Under Material Handling Systems from mk North America

Over under conveyor systems from mk North America are a great way to control production rates, boost productivity, free up usable floor space in your production area, and more. A broad range of system modules like vertical transfer units, rotation and transfer units, positioning units, and pallet stops allow you to perfectly engineer your system to meet application requirements.Asynchronous pallet conveyor systems from mk come in three basic configurations: the VersaMove Standard, Plus, and Ultra lines. Each configuration is suited to distinct and uniquely challenging production and material handling environments. Some features include:

- Accommodation of pallet sizes between 6 inches and 48 inches

- Pallet loads of up to 1,000 lbs. with the VersaMove Ultra

- Line speeds of up to 200 fpm

- Short lead times

Industrial Applications for Over Under Conveyors from mk North America

VersaMove systems set up as over under conveyors are useful in just about any industrial application where flexibility, efficiency, and optimal use of limited floor space are valuable. In particular, the potential for sophisticated automation using custom modules makes over under systems and other mk pallet conveyors useful in the automotive and electronics manufacturing industries. Other industrial applications include general manufacturing, machine building, assembly lines, packaging and others.

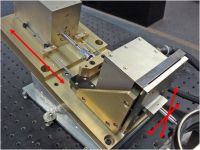

SMAC offers a wide range of programmable electric actuators based on Moving Coil linear servo motors. All SMAC actuators are fully programmable permitting the user to exert complete control over force, acceleration, position and velocity. This makes it ideal for implementation in industries where SMAC’s patented ‘Soft-Land’ procedure allows the actuator to both measure and manipulate very delicate and high value components with ease.

SMAC offers a wide range of programmable electric actuators based on Moving Coil linear servo motors. All SMAC actuators are fully programmable permitting the user to exert complete control over force, acceleration, position and velocity. This makes it ideal for implementation in industries where SMAC’s patented ‘Soft-Land’ procedure allows the actuator to both measure and manipulate very delicate and high value components with ease.

nnrnnn nnrnnn

nnrnnn nnrnnn