Built-in Controller Type RCP6S

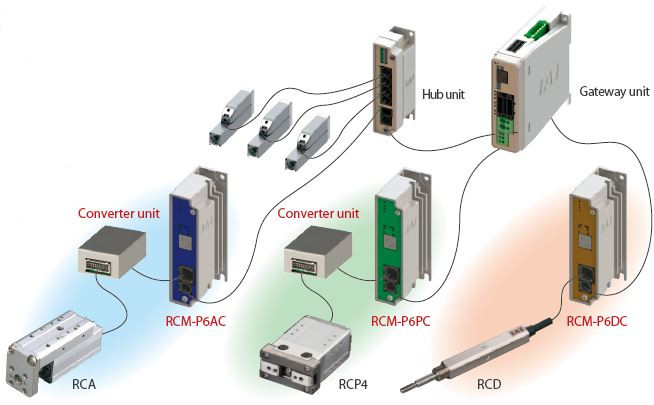

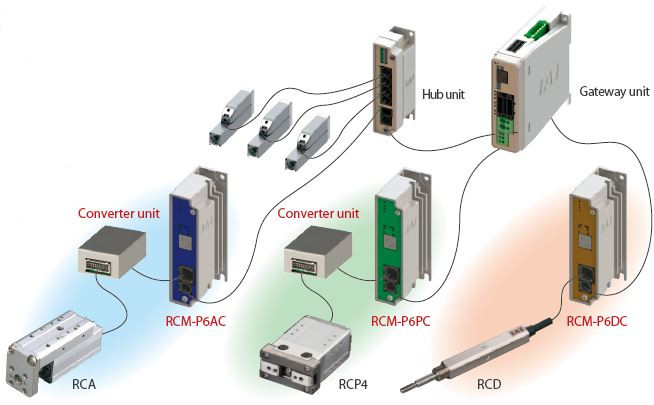

Standard/separate controller type RCP6 or built-in controller type RCP6S can be selected for all models. A maximum of 16 axes of RCP6S (relayed through a hub unit) can be connected to one gateway unit. In addition, the gateway unit can supply the motor power and control power needed for all connected axes, therefore only requiring one cable (power and communication line) for the RCP6S.

RCP6S with built-In controller advantages:

- Control panel can be smaller

- Wiring can be easier

- Reduced maintenance parts since a common cable is used

RCP6S Gateway Controller

This controller can connect RCP, RCA, and RCD series actuators to an RCP6S gateway unit and hub unit.

Mini ROBO Cylinders and gripper type actuators can be added to the RCP6S network.

RCP6 Product Types

- Rod Type

- Radial Cylinder Type

- Wide Type

- Table Type

- Slider Type

- Cleanroom Slider Type

- Cleanroom Wide Slider Type

- Dust/ Splash-proof Rod Type

- Dust/ Splash-proof Radial Cylinder

- Dust/ Splash-proof Wide Radial Cylinder

Features of the Wide Type

(1) Wide Slider Type: Allowable dynamic moment is 14 times higher than the standard slider.

(2) Wide Radial Cylinder: Allowable torque on the rod tip is 3 times higher than the standard radial cylinder.

Equipped with High Resolution Battery-less Absolute Encoder as Standard

Battery maintenance is not required because there is no battery.

Since home-return is not required at equipment startup or after an emergency stop, this feature reduces operation time and production costs.

Price is the same as the conventional incremental encoders.

Improved Positioning Repeatability for Standard Specification: ±10μm

±20μm of positioning repeatability for the

current ROBO Cylinder has improved.

Selection of PowerCON® Compatible Controllers Is Available

The RCP6 is compatible with PowerCON, the controller equipped with a high-output driver.

The stepper motor achieves higher output, thanks to the PowerCON. This has reduced production cycle time, leading to improved productivity.

You can choose from two controllers with PowerCON: the “separate type” and “built-in type”.

Click here for more information and product catalog.

For more information on the ELECYLINDER contact any one of the team members @ Blettner Engineering or by calling 317-862-9580.