| rn

Mecco Marking & Traceability & Blettner Engineering (Representing Mecco in the state of Indiana) is striving to make laser marking systems affordable for every company. We are working with a strong financial partner to create a new payment plan for laser marking systems and certain configured laser marking system leases are available for approximately $1,000 per month.nnrn

If you are using paper labels or paying to send your parts out to be marked by another company then laser marking your own parts might save you money.nnrn

nnrn nnrn

Mecco has been in the industrial marking business since 1889 and sells a variety of dot peen and laser marking systems. Mecco manufactures lasers systems in CO2 and YAG wavelengths and in several power levels.nnrn

nnrn

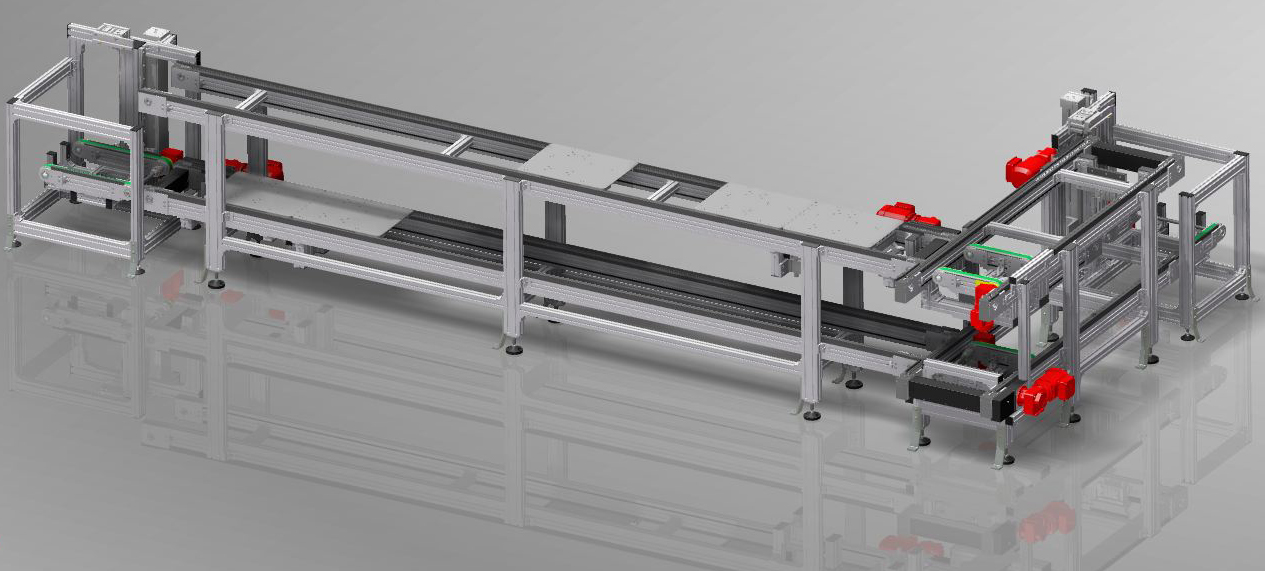

If your production requires a turnkey workstation Mecco can manufacture the Class 1 station to meet most needs including automation and production line integration.nnrn

nnrn nnrn

Blettner Engineering would like to discuss with you your marking application. Blettner Engineering is also available to conduct a laser or dot peen marking system demonstration at your location. (based on scheduling) nnrn

If you’re not able to make an appointment for an onsite demonstration we can always make arrangements to send your parts to Mecco for a free application test marking.nnrn

rn

For more information on Mecco products contact one of the sales staff at Blettner Engineering or visit http://www.mecco.com to learn more.nnrn

nnrn

nnrn

rn

rn

rn

| rn

nnrn

rn

Dale Blettner

rnnnCentral &nnSouthern Indianannrnnnnn

rnnnnn

- Office: 317-835-7168

nnnnrnnnnn

- Fax: 317-835-7158

nnnnrnnnnn

- Cell: 317-432-1514

nnnnrnnnnn

- dale@blettnerinc.com

nnnnrn

nnnnrn rn

rn

Trent Blettner

rnnnSouthern IndianannKentuckynnSouthwest Ohionnrnnnnn

nnnnrn rn

rn

Craig Frazee

rnnnNorthern Indianannrnnnnn

nnnnrn rn

nnrn

nnnnrn

nnrn

nnrn

nnrn

nnrn |

rn

rn

rn

rn

nnnnrn

This offer is based on acceptable credit and an example price for a laser marking system that includes a 20 watt pulsed YAG wavelength fiber laser marking system, graphical interface laser marking software and Class I laser safe standard desktop workstation with manual focus adjustment. Leasing options should be available for all of our laser marking system.nnrn |